.png)

VRL Vural Plastik ve Kalıp Sanayi A.Ş. provides high-quality transport and storage solutions for the defense industry. The company develops custom solutions for military and industrial needs using primarily plastic, as well as wood and composite materials. Its transport crates, protective cases, custom-sized bags, and various plastic components offer maximum durability and security under harsh conditions. UN code certification proves that the products meet international transport standards. As an approved supplier of the General Directorate of Military Factories, the company also offers supportive services such as foam inserts, ultrasonic welding, and CNC router processing.

The Plastic Püsüs Assembly is a specialized product designed for the safe transportation and storage of modular propellant systems and ammunition. Thanks to its advanced manufacturing method and optimized design, it offers high durability and superior protection against impacts, environmental factors, and outdoor conditions. Its ability to be manufactured in various types and dimensions provides flexibility to meet a wide range of application needs.

The plastic transport case is specifically designed for the secure transport and storage of critical equipment and materials. Its high structural strength and advanced sealing capability provide maximum protection against physical impacts, environmental conditions, and contamination risks. The case can be manufactured in various dimensions to meet specific operational requirements and mission profiles.

Wooden transport crates are specifically engineered and manufactured for the secure shipment and storage of sensitive and mission-critical equipment. Our UN-certified models are compliant with international regulations and are suitable for the safe transportation of hazardous materials, including explosive substances classified under IMDG, ADR, and IATA guidelines. The interior of each crate is custom-fitted based on the specifications of the payload. Foam inserts are designed and installed in-house, tailored to ensure maximum protection during transport. We offer both ESD-protected and standard (non-ESD) high-density foam options, selected according to operational requirements.

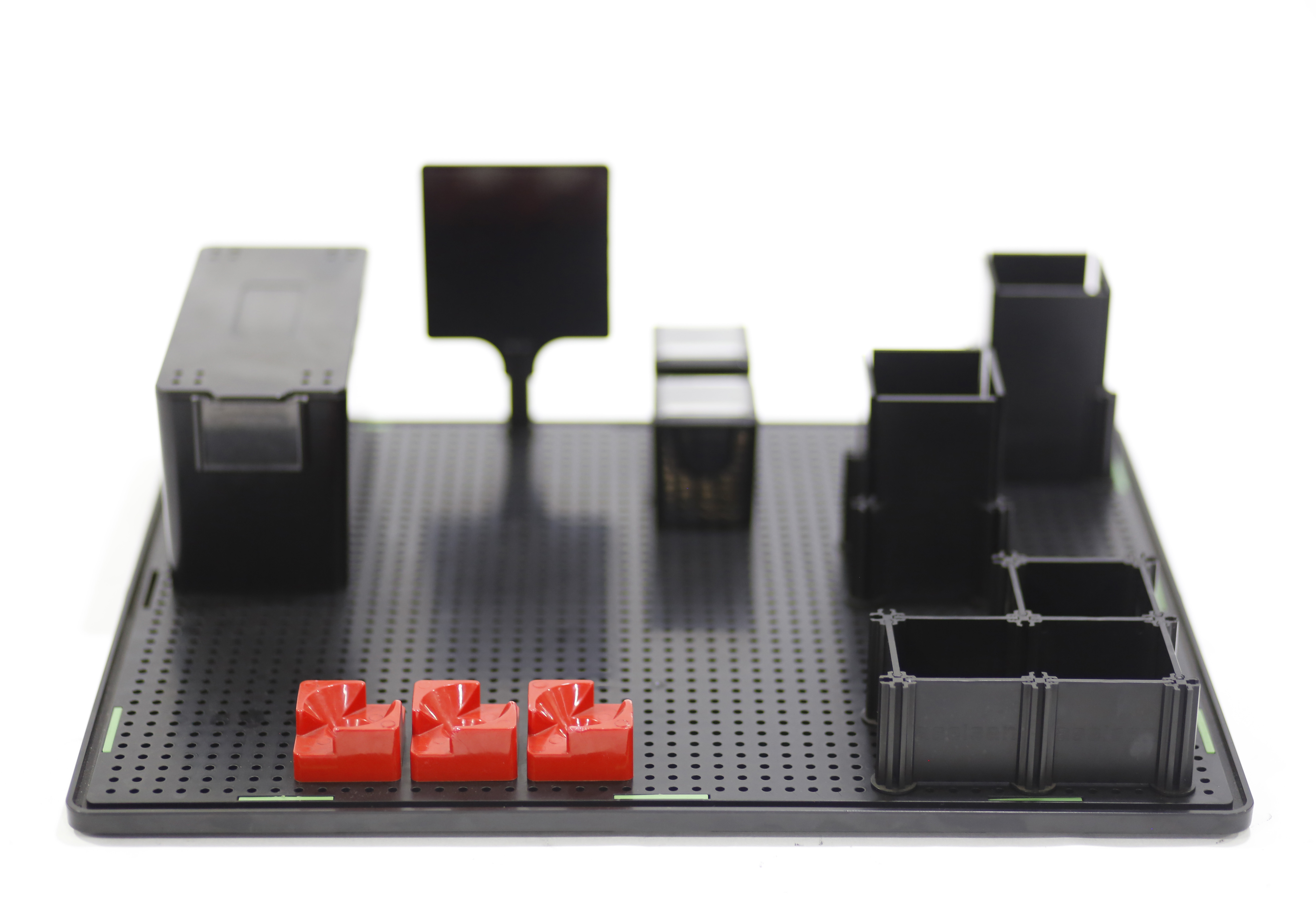

This product is designed to provide effective protection against electrostatic discharge (ESD) during operations involving electronic components. Its modular structure allows for flexible placement of various parts and components, enhancing operational efficiency particularly in assembly, maintenance, and testing phases. The full set includes boxes of various sizes and customizable divider systems, ensuring adaptability to specific technical requirements. It is well-suited for use in sectors requiring high reliability and precision, such as the defense and aerospace industries.

We ensure the highest level of security for your mission-critical products through the manufacturing of protective and transport cases in various types and sizes. We offer fully customized solutions tailored to the specific requirements of our clients; from design to production, we select the most suitable manufacturing methods based on the intended use and operational needs to deliver flexible and optimized products. This approach allows us to provide durable and functional protective solutions that fully comply with the stringent standards of the defense industry.

Plastic transport cases are specially designed for the safe transport and protection of critical equipment and materials. With their high structural strength and advanced sealing features, they provide maximum protection against physical impacts and harsh environmental conditions, enhancing operational safety. They can be manufactured in various sizes to meet different mission profiles and operational requirements, offering flexible solutions for all kinds of logistical scenarios. Custom sizes are available to suit specific operational needs and mission requirements.